Optimising Dairy Packaging for High-Volume Periods | Inspiron

SPONSORED CONTENT

Why compromise between speed and quality when demand puts pressure your production line?

For cheese packing businesses, with automatic lines, it’s vital that operations run efficiently all the time. Unscheduled maintenance or malfunctions can have dire consequences for products with a limited shelf life, and any losses incurred due to missed deliveries are impossible to recoup.

In many operations, production lines are set up using several types of equipment, each running as a stand-alone machine. Each machine will likely have its own dedicated interface, configured for a specific action and containing its own data base. Even the functions will be designed around the production task.

While it’s possible for a database from one machine to be transferred to an identical one, it isn’t possible to share data between machines supplied by different manufacturers, no matter how similar they appear. However, equipment installed by a single provider can access a central database, set up by the manufacturer.

Having a line of individually controlled machines, all needing the same information and parameters inputting (batch numbers, dates etc.), can increase the risk of manual error. One incorrect piece of code input into the machine could result in the wrong data on packages. The knock-on effect of tracing the error and repackaging is both frustrating and costly.

When demand is high and production needs to speed up to meet that demand, the likelihood of errors increases. Unfortunately, so does the cost of rectifying mistakes down the line – literally!

At Inspiron, our twenty-five years of supporting clients means we understand the challenges faced by the dairy industry. We’ve embraced technology designed to meet operational objectives and deliver a competitive advantage.

For example, with XTrace.app, a production management system, it’s possible to integrate production machinery from various manufacturers, using our end of line outer case marking system (OCM). This effectively becomes the master terminal for the entire line.

Linked to a central database that holds all product, label and machine programme information, XTrace.app can also communicate with Enterprise Resource Planning (ERP) and accounting systems.

The OCM controls production and maintains consistency throughout the production cycle. The operator simply selects the required product from the production plan and the batch number. The correct dates are calculated automatically, from pre-set parameters and, once set up, the system sends identical data to other, connected machines. This ensures that data such as label numbers, product text, ingredient lists, batch numbers, pack dates, expiry dates and unit prices are all uniform across the production run. It’s clear to see that this central processing system mitigates manual errors across lines and improves efficiency.

Even with machines programmed from a central source, glitches may still occur. A pack label may be askew, the print quality unsatisfactory or a seal incomplete perhaps. However, a robust system will detect these anomalies immediately and prevent the product reaching the customer. We advise that producers add a Vision Inspection system at the end of each packing line, prior to boxing.

Vision systems operate effectively, whether centrally controlled or individually programmed. They spot badly labelled packs, packs with incorrect information, the wrong wrappers or badly sealed packs. Anything outside of the pre-defined limits is rejected from the line. If multiple rejections reach a set limit (determined by the operator or pre-set programme), a signal is sent to halt the line and rectify the issue.

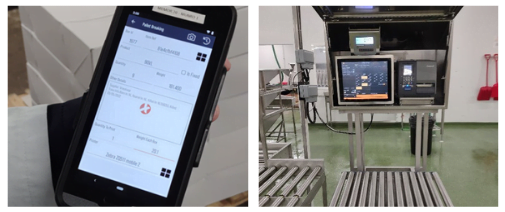

In the case of a centrally controlled line, the relevant data from all connected machines is transmitted to the XTrace.app database and stored there. The web-based user interface allows the operator to view real time production information, including if the line is on schedule, how efficiently it’s running and any statistics that might necessitate intervention. This is done via monitors, located in the hall and displaying informational graphics related to the run.

XTrace.app goes further than just monitoring packing. There are options to include stock and despatch modules that allow operatives to see product stock by production dates or use by dates, all in real time. When the boxed product is registered by the OCM, it is added to the XTrace box stock. Boxes are palletised per customer order and scanned using hand-held terminals. When the individual pallet bar code labels are printed and applied, the boxes are moved into ‘palletised stock’. Once loaded for delivery, the Pallet barcodes are scanned again, moving the stock into ‘despatch’.. Finally, order despatch details are communicated to the ERP / accounting software for invoicing, completing the circle and creating trackable data.

While these machines and related systems are valuable to producers and their day-to-day schedules, a set up like the one described here has far reaching benefits at times of increased demand, when problems are more likely to occur.

Inspiron’s equipment, together with flexible service and maintenance plans, which prioritise fast response to breakdowns, provides the industry with superior levels of support and expertise. To protect your facility, ask us to conduct a no-obligation audit of your operation and discover how Inspiron can help meet demand.

Visit Inspiron Systemsor call them at +44(0)1788 890235 to learn about their solutions for improving your dairy operations.