Removing Steps, Unlocking Time: ZwitterCo Evolution Membranes

ZwitterCo Evolution Membranes Transform Cleaning Programs in Dairy Processing

SPONSORED CONTENT

Cleaning programs are the costliest and most resource-intensive aspect of membrane operation in dairy plants. Membrane systems used for whey protein concentration, milk processing, and effluent treatment are especially prone to fouling from fats, proteins, and other organics. Membrane cleaning programs are long, chemical-intensive, and consume valuable production hours. In a typical cheese plant processing their whey, at least two-thirds of the chemical spend is specialized formulated cleaners for the membrane systems.

The Evolution membrane portfolio from ZwitterCo addresses this challenge directly. Built from zwitterionic chemistry, these membranes are inherently anti-fouling and fully recover performance with fewer cleaning steps. The result is shorter cleaning cycles, reduced chemical demand, and more time available for production...and, of course, cost savings!

Zwitterionic Chemistry and Fouling Resistance

The differentiation lies in the chemistry. Evolution membranes are made with zwitterionic copolymers that are exceptionally hydrophilic. Zwitterions carry both positive and negative charges, binding strongly to water molecules and creating a hydration layer on the membrane surface. This hydrated layer prevents proteins, fats, and other organics from adhering to the membrane surface, which is the primary cause of flux loss in conventional membranes.

In practice, this means that foulants which normally require an enzymatic step to remove can be removed with a simpler wash. Evolution membranes consistently achieve full flux recovery without the costly and time-intensive enzyme wash.

Simplifying Cleaning Programs

| Cleaning with Conventional Membranes | Optimized Cleaning with Evolution Membranes |

|---|---|

| Water Flush | Water Flush |

| Alkaline Wash | Alkaline Wash |

| Water Flush | Water Flush |

| Enzyme Wash | |

| Water Flush | |

| Acid Wash | |

| Water Flush | |

| Alkaline Wash | |

| Water Flush | |

| Sanitization | Sanitization |

| Water Flush | Water Flush |

The economics are substantial. In one analysis, replacing conventional UF with Evolution membranes reduced chemical costs from £368/day to £108/day, halved water use, and lowered wastewater treatment expense by more than half. Total annual CIP cost dropped from £453,620 to £182,040, delivering net savings of over £271,080 per year for a single site.

Side-by-side comparisons highlight the impact.

Application-Specific Advantages

- Evolution RO : While awaiting regulatory approval for food contact applications, Evolution RO has been used to concentrate a number of effluent and wastewater streams. These anti-fouling RO membranes have been proven to eliminate the enzyme step in cleaning programs. Commercial installations have demonstrated >50% chemical cost reduction, >40% less cleaning-related water use, and one hour or more of recovered production time per day.

- Evolution SF (Superfiltration): FDA-compliant for whey and milk processing, Evolution SF replaces tight UF or loose NF membranes. It is designed for high-solids and high-fat applications, maintaining flux stability and recovering easily from simpler cleaning programs.

- Evolution PCM (Protein Concentration Membrane): PCM is a sanitary UF membrane designed to replace conventional 5-30 kDa UF membranes in a variety of food and dairy protein concentration applications. With their anti-fouling zwitterionic chemistry, Evolution PCM spiral elements can enable the simplest membrane cleaning program ever for protein concentration.

Validated Performance

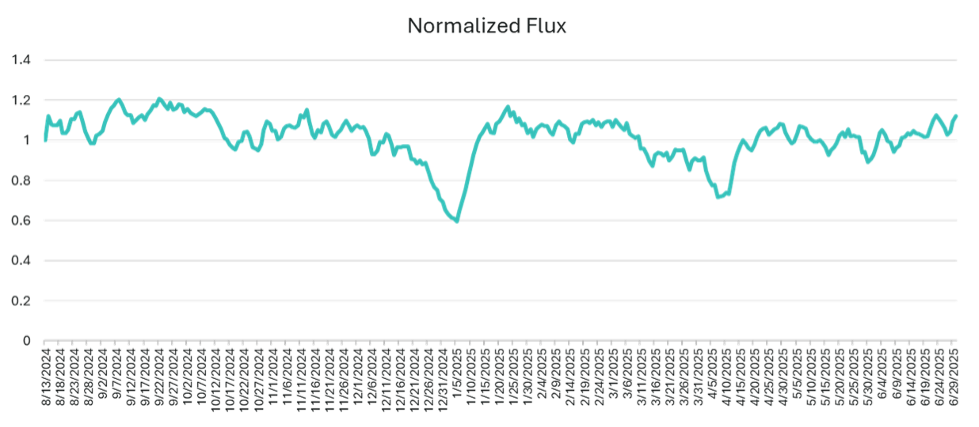

Field data confirms these improvements. In a whey processing effluent application, Evolution RO elements have operated for more than a year without a single enzyme wash. In addition to proving the ability to remove the enzyme cleaning step, Evolution RO reduced chemical costs by 56%, and lowered water use by 41%, all while maintaining the same normalized flux as when they were first installed.

Integration with Existing Systems

Evolution membranes are manufactured in industry-standard sanitary spiral formats. They are designed as direct replacements for conventional elements, requiring no equipment changes or CAPEX. Plants can implement them and immediately benefit from simplified cleaning and reduced operating costs without disrupting production.

Implications for Dairy Processors

By removing cleaning steps and shortening cycle times, Evolution membranes free 1–2 hours or more of production per day, cut chemical usage by more than 50%, and significantly lower water demand and wastewater volumes. For large whey protein isolate (WPI) or milk protein concentrate (MPC) facilities, these gains add up to meaningful improvements in throughput, operating efficiency, and sustainability performance.

Conclusion

Cleaning costs, time, and large chemical and water requirements required for membrane cleaning has long been a target for optimization. With ZwitterCo Evolution membranes, processors now have the membrane option they’ve been looking for to simplify cleaning programs, eliminate enzyme steps, and restore full performance with shorter, lower-cost protocols. For an industry where every hour of uptime and every liter of water counts, Evolution membranes represent not just incremental improvement, but a fundamental shift in how cleaning programs can be managed.

Contact ZwitterCo today to explore how we can advance your dairy processing capabilities.

More information - https://zwitterco.com/