Optimising Cheese & Dairy Processing | ZwitterCo

Cost Savings, Efficiency, and Sustainability with ZwitterCo Membranes

sponsored content

The dairy and cheese processing industry faces increasing pressure to enhance efficiency, reduce costs, and operate more sustainably. From milk standardisation to whey concentration, the industry relies on advanced separation technologies to ensure product quality, maximise yield, and meet stringent regulatory requirements. Membrane filtration plays a vital role in processes such as ultrafiltration (UF) for protein standardisation and concentration, microfiltration (MF) for bacterial removal, and reverse osmosis (RO) for whey concentration and water recovery. These applications are essential for optimising production efficiency, minimising waste, and enhancing product consistency across a wide range of dairy and cheese products.

As manufacturers seek to streamline production and improve profitability, advanced membrane technology is proving to be a critical enabler of operational excellence. Traditional filtration methods often suffer from fouling, high chemical consumption, and frequent downtime due to intensive cleaning cycles. ZwitterCo’s innovative membrane solutions directly address these challenges by offering superior resistance to fouling, which enables significantly shorter and easier cleaning cycles (CIPS). This combination of benefits results in tangible cost savings and environmental advantages, making ZwitterCo membranes an indispensable asset for forward-thinking dairy producers.

Substantial Cost Savings: Over £1,000 Per Membrane Element

Cost control is critical in dairy processing, particularly in whey concentration, milk protein isolation, and lactose separation.

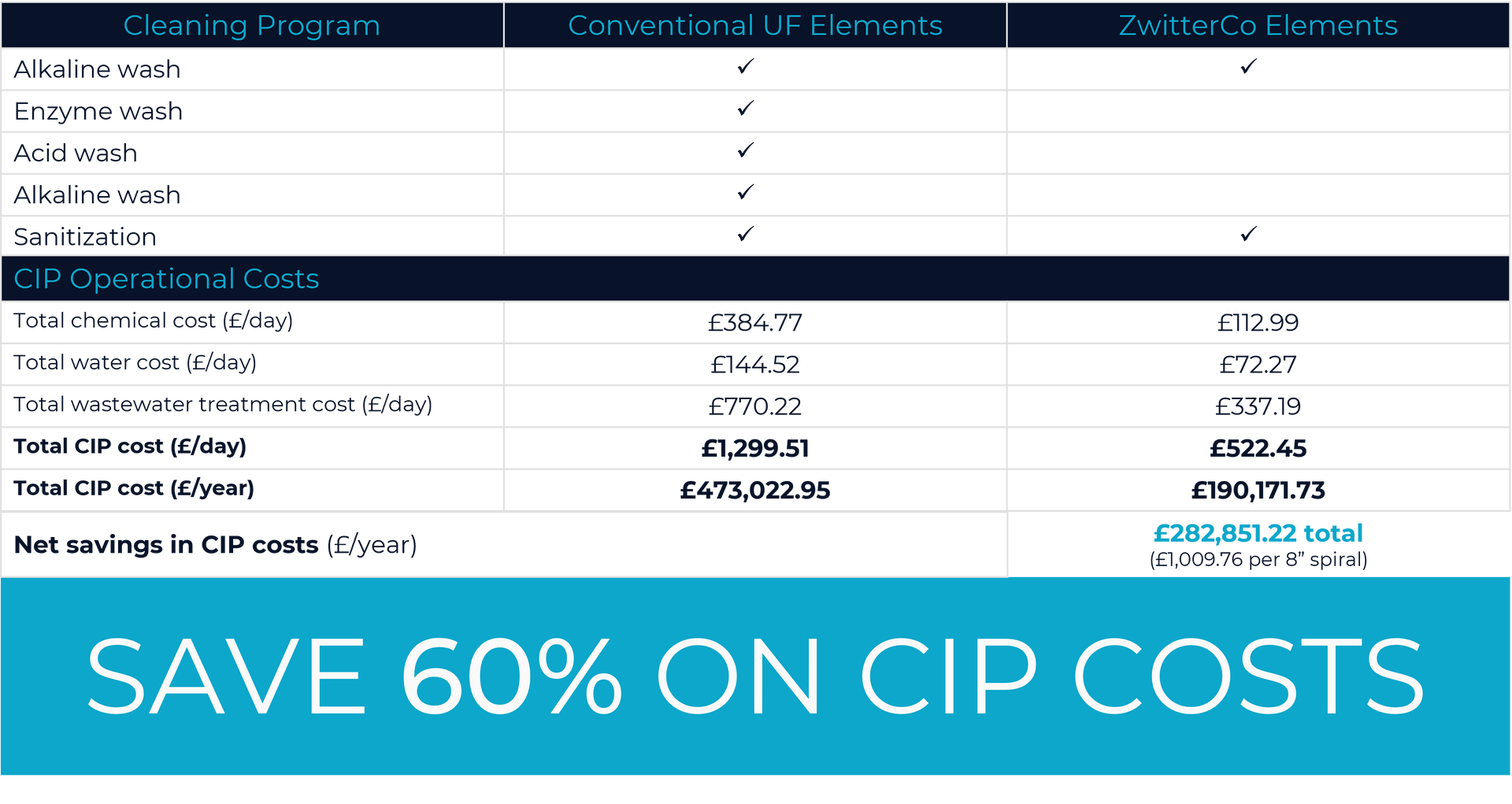

ZwitterCo’s advanced membrane technology significantly shortens and simplifies Clean-in-Place (CIP) cycles, resulting in savings of over £1,000 annually per membrane element. By reducing the number of steps required in CIP, operations save substantial amounts of chemicals, water, and energy previously consumed in flushing and recirculating cleaning solutions.

With shorter CIP cycles, processing facilities gain valuable uptime, enabling increased production capacity or optimised workflow. When multiplied across numerous membrane systems, these efficiency gains translate into considerable overallcost savings and improved profitability throughout the dairy processing supply chain.

Streamlined Cleaning Programs: Up to Six Fewer CIP Steps

These processes demand significant water, energy, and chemical inputs, increasing both costs and downtime.

ZwitterCo’s breakthrough membrane technology is immune to irreversible organic fouling, setting a new standard in dairy processing. By leveraging the extreme hydrophilicity of zwitterions, these membranes form water-loving channels that prevent organic compounds from adhering to the surface.

This advanced fouling resistance enables dairy producers to simplify their cleaning protocols by eliminating up to six CIPsteps, including sanitisation and flushes. As a result, plants experience significantly shorter turnaround times, reducedchemical and water use, lower energy consumption, and greater uptime - boosting productivity while advancing sustainability goals.

A Forward-Thinking Approach to Whey and Milk Processing

As the global demand for protein and other dairy products continues to rise, processors must adapt to shifting market dynamics, evolving consumer expectations, and increasingly stringent sustainability mandates. By integrating ZwitterCo’s advanced membrane technology, manufacturers can achieve measurable financial benefits, operational efficiencies, and a reduced environmental footprint.

With tangible cost savings exceeding £1,000 per membrane element, a more streamlined and efficient cleaning process, ZwitterCo is setting a new benchmark for innovation in dairy processing. As the industry evolves, adopting advanced solutions will be crucial for processors aiming to remain competitive through greater efficiency, sustainability, and reduced operating costs.